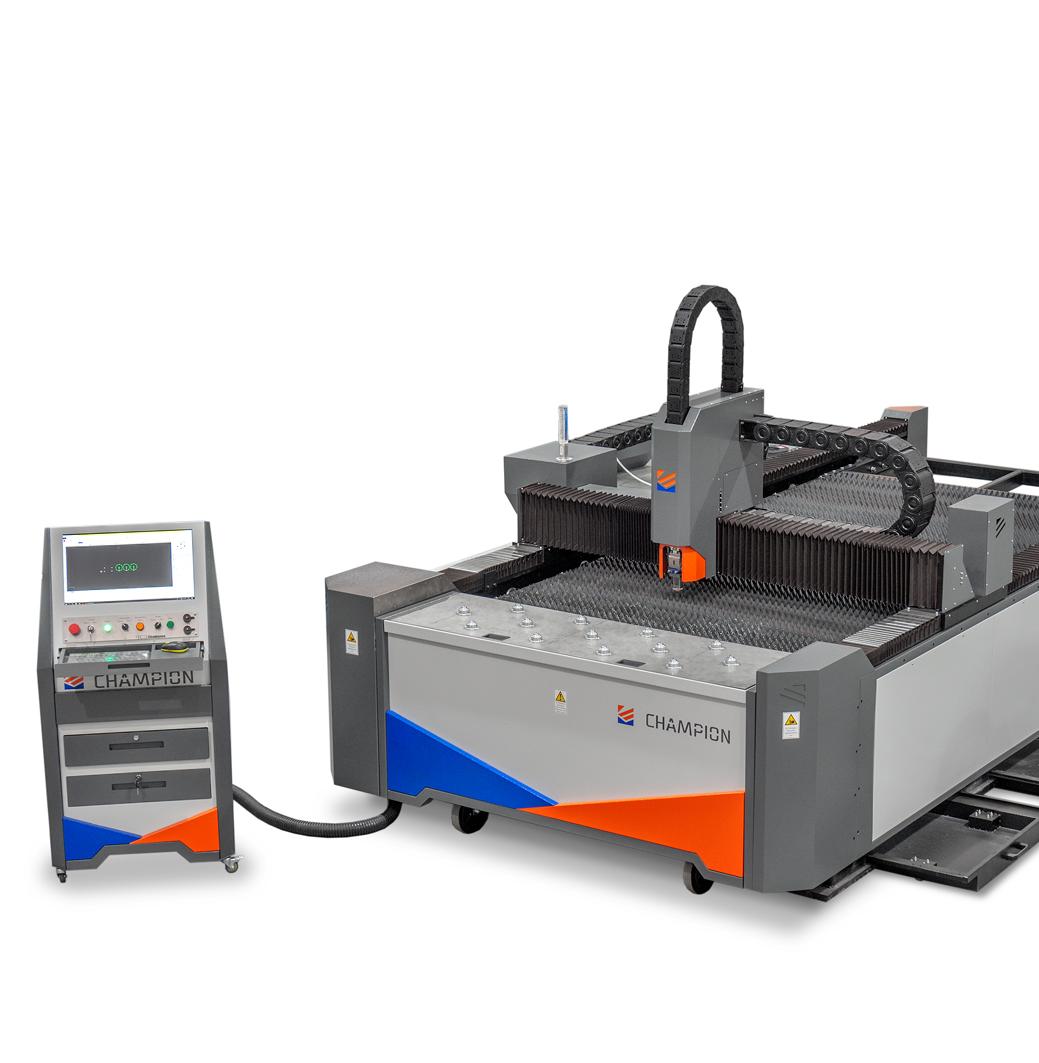

Kinematics of our machines

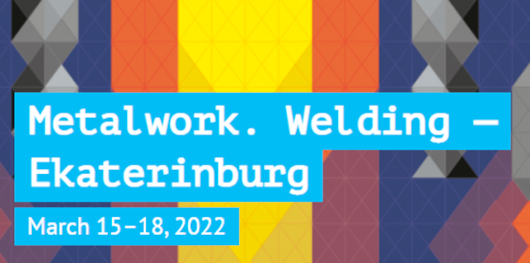

Laser cutting machines manufactured by the Chelyabinsk Laser Equipment Plant are built according to the classical kinematic scheme with three independent coordinates used by almost all manufacturers of such equipment. On the one hand, this is good, since proven solutions are used, but on the other hand, you need to somehow stand out from the competition.

Due to the optimal selection of components, load modeling and original design solutions, ChLEP offers the consumer machines that are at least as good as competitors in terms of characteristics, but have more attractive prices. At the same time, the estimated resource is at least 10 years when working 24/7.

An analysis of the designs of laser cutting machines has shown that they often use components from well-known manufacturers, which leads to some, sometimes significant, overpayment "for the brand". At the same time, the market offers products from less well-known manufacturers with comparable characteristics.

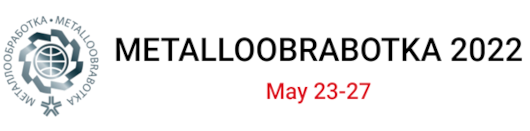

Chelyabinsk Laser Equipment Plant successfully cooperates with Nietz, a major manufacturer of electromechanical equipment from China. A wide range of servos and planetary gearboxes, which is not inferior to famous analogues, characteristics, as well as the readiness of the operational manufacture of components with the parameters required by the client, allow us to create equipment with optimal accuracy and performance. To ensure optimal performance on each machine, ChLEP specialists adjust the parameters of the servos, focusing on experimental data on the dynamic characteristics of the electromechanical system of a particular machine.

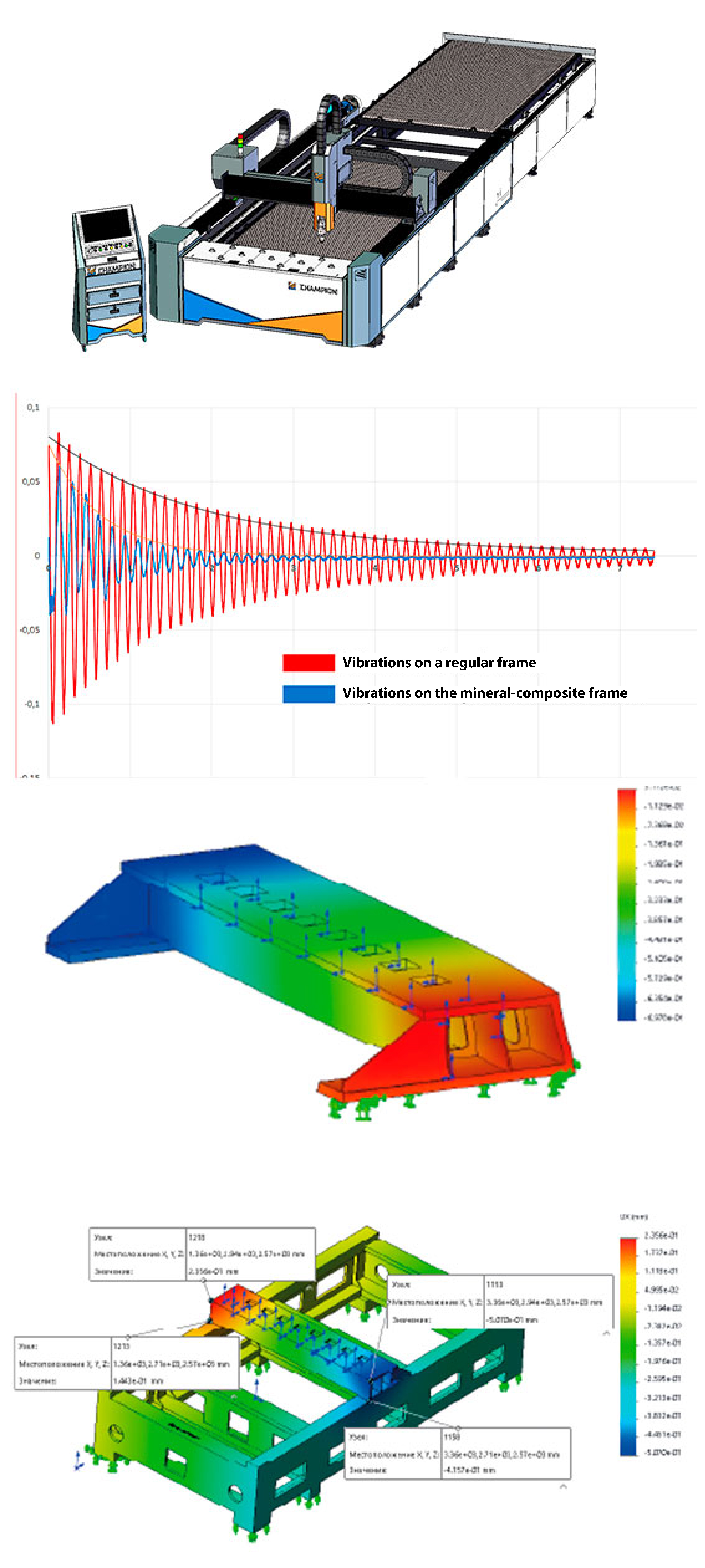

Modeling of static and dynamic loads arising in the machine allowed us to use rail guides of a smaller standard size in comparison with competitors without compromising the accuracy and resource parameters of the machine. The use of pre-tensioned carriages reduced positioning errors and increased the smoothness of movement.

The combination of measures carried out during the design and carried out during manufacture made it possible to establish serial production of machines with high consumer characteristics: the speed of movement of the laser head up to 100 m/min or 140 m/min (depending on the model), acceleration - up to 1.2g or 1.5g (depending on the model) with cutting errors corresponding to 7-12 qualities.